Today, people want their laptops to be slim but also powerful at the same time. These requirements are opposing because a more powerful laptop generates more heat which in turn, requires bulkier thermal dissipation devices such as heat sinks and fans.

In laptops, there is not enough space to mount a heat sink directly on top of the CPU. Heat is instead first taken away from the CPU by an ingenious device called a heat pipe and then dissipated through a radiator and a fan. The efficiency of a heat pipe therefore plays a critical role in the thermal performance of a laptop.

Heat pipes, despite being an old technology first developed by NASA in the 60s, continue to be indispensable in consumer electronics and thus are subject to constant improvements and innovations.

We dived deep into patents on heat pipes to find some interesting ways of improving their performance. In this post, we list some interesting ideas we came across. Thermal design engineers can use such ideas to push the boundaries with their next products.

#1 Heat pipe passing through the hinge

An interesting thing to observe about a typical laptop is that its heat sinks are located below or around its main body. There is not much opportunity to radiate heat around these surfaces. On the other hand, there is a lot of free space around the back cover of the display and yet it takes no part in heat dissipation.

Heat pipes can, however, be made to pass through the laptop hinge and thus transport heat to the back frame of the display, where it can dissipate much more easily. (Source)

#2 Maximal use of the heat pipe

Heat pipes used in laptops are often designed conservatively so that ‘dry out’ condition (when all the working fluid gets evaporated) does not happen even during peak performance.

It is possible, however, to squeeze out much more capacity from the same heat pipe with intelligent control. By taking into account the amount of working fluid available and the dynamics of the heat pipe, a laptop CPU can easily be pushed into ‘boost mode’ without overheating. (Source)

To do this, the thermal controlling chip can use heat pipe parameters to predict how far it can be pushed before reaching a dry out condition, and once it is reached, how much time it will take to come back to normal state. Such a control scheme can deliver the same workload with a smaller heat pipe or more compute workload with the same sized heat pipe.

#3 Aerogel based wicks

The inner surface of heat pipes typically carry a wick. It provides a pathway for the condensed fluid back from the condensation chamber to the evaporation chamber.

The wick is usually made up of metal, typically copper, but much better performance can be obtained with a wick made up of a graphene based aerogel with a density of 0.03-0.5 g/cm3 (Source). Graphene based heat pipes have been shown to have 3 times higher heat dissipation capacities than commercial copper based heat pipes.

#4 Geometry of the heat pipe

The geometry of a heat pipe affects its heat transfer characteristics. It has been reported that by keeping the middle part of a heat pipe thicker than either of its ends, the cooling capacity is increased by virtue of its reduced thermal resistance. (Source)

#5 Actively push fluids

By actively pushing the working fluid from the evaporator section of a heat pipe towards its condensation section and back, more heat can be transferred by the pipe per unit time. Such a forced flow can be realized with piezoelectric elements that can be installed in the heat pipe. These piezoelectric elements vibrate at high frequencies to produce vibrations and can act as miniature fluid pumps. (Source)

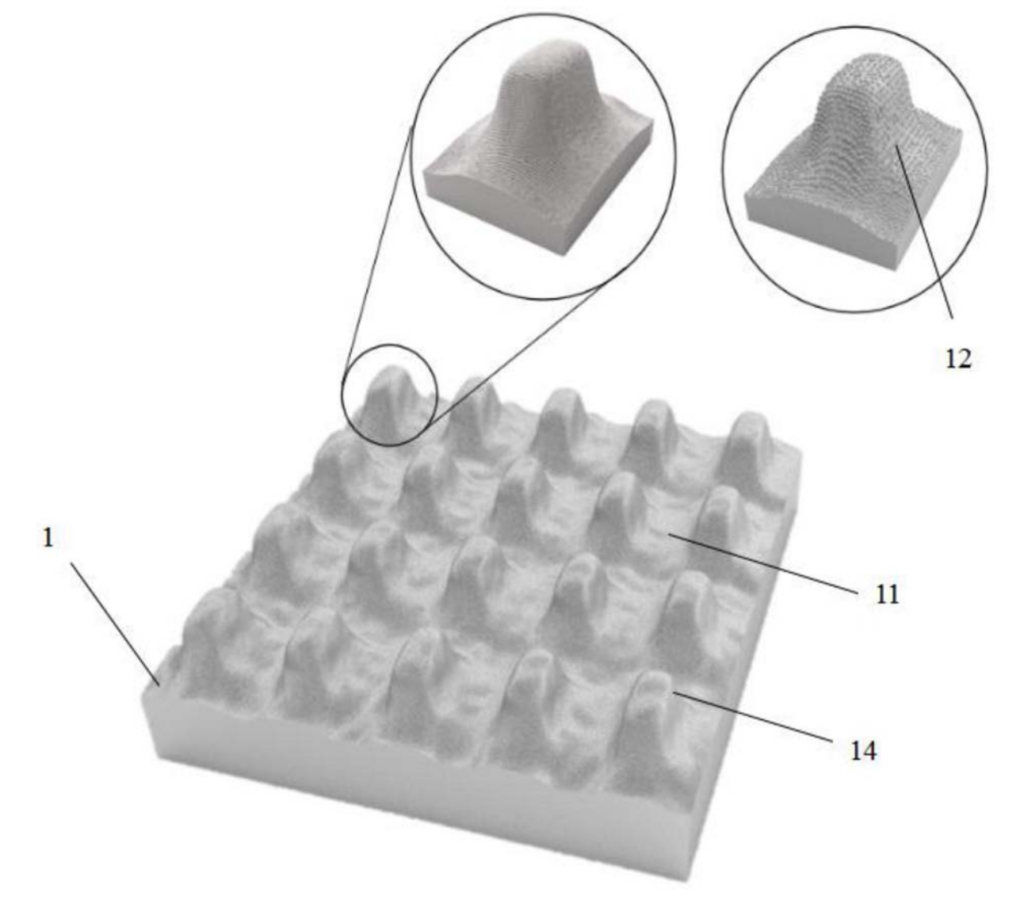

#6 Hydrophilic coating

A hydrophilic coating on the inner surface of the heat pipe with micro substructures can improve the evaporation capacity based on a high-temperature bubble nucleation evaporation mechanism. The material for the coating can be SiO2 or TiO2 and micro substructures can be provided by micrometer level protrusions on the inner surface. (Source)

As with any other technology, patents contain a mind-boggling variety of ideas on how to improve heat pipes. The above list should only be considered as representative because there are more than 15,000 patents related to heat pipes published worldwide.

That’s why I strongly recommend product design teams to make patent exploration a regular activity. It is one of the best way to bring next-level innovation in your products quickly and easily.

Subscribe to our newsletter to receive insights on using innovation data for product development.

Cover Photo by Vishnu Mohanan on Unsplash