Inkjet printers work by dropping tiny ink droplets on paper at precise locations. These droplets are so small that you could make a billion of them from just one drop of ink.

The first inkjet printer was invented in 1970. By the 2000s, the technology had matured. A dozen companies, such as HP, Canon, Epson, etc., were manufacturing and selling more or less similar inkjet printers.

Even at this stage however, there was one big problem with all printers – they were slow.

They were slow because the print-heads were small in size and could not cover the entire page. A printhead is basically an ink chamber with nozzles at the bottom from which the droplets come out.

If a printhead is smaller than the page, it has to constantly travel to-and-fro to cover the entire page. This is why inkjet printers make a rhythmic noise while printing.

Many companies had contemplated bigger print-heads, but it was thought largely impossible. The limits of manufacturing technology presented difficulty in making large number of nozzles on a single surface.

Then came on the map a little company called Memjet! New player in the town, late to the party.

In an established industry, newcomers have little chance of survival. Unless they do something big and disruptive.

Fortunately, Memjet thought big and it acted disruptively:

In contrast to most other competing inkjet technologies, Memjet has focused on single-pass technology from the outset. This is a result of our earliest internal research lab discussions that explored how to develop “the ultimate” printing technology.

Mike Puyot, President, Memjet Product Development

Memjet announced their first print-head. It would be 8.8 inches long. It would have 70,400 nozzles. It would cover the entire width of A4 sheet. Therefore, it would print A4 pages in a single pass and would not need to move.

The industry’s reaction was – disbelief.

Experts thought it was a hoax!

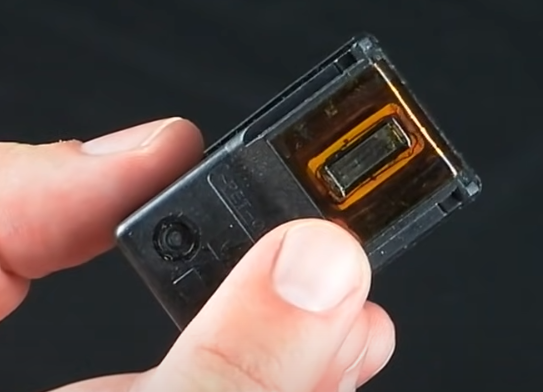

To understand the basis of their scepticism, look at this. Here is a typical inkjet printhead (the area inside the orange rectangle usually has up to 1,000 nozzles):

And here is what Memjet’s promised printhead (the brown strip running through the middle has 70,400 nozzles)

The scepticism evaporated immediately when Memjet’s printheads began appearing in printers, their specifications matching word-to-word to what had been announced.

How had Memjet done it? People couldn’t wrap their heads around it for a long time!

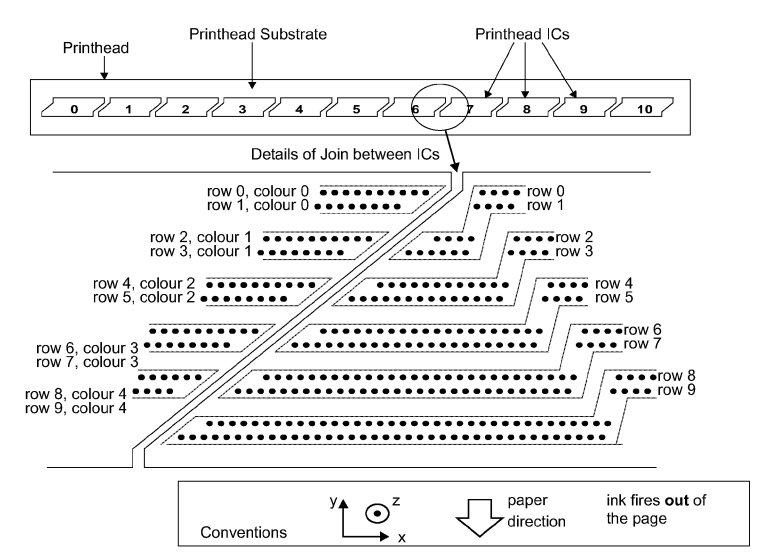

First, Memjet created a superb quality print-head but they couldn’t make it as wide as they wanted. So they came up with an ingenious way to join these printheads in such a way that there was no “gap” between the nozzles of one head and another, as seen along the paper’s length. See image below from one of Memjet’s patent:

They called this technique ‘dropped triangle’ and it completely changed the game. With this technology multiple printheads could effectively be joined and made to act as if they were just a single head.

Now you might be wondering who was this visionary who had the tenacity to imagine and build such a thing? Well, it was all led by the prolific Australian inventor, Kia Silverbrook, who has thousands of patents related to this technology in his name.

The story of Memjet and Kia Silverbrook shows how long-standing industries can be disrupted by a few visionary innovators.

When you work in an industry for a long time, your insider experience becomes a hindrance. It limit your imagination about what is possible in your domain.

Our newsletter regularly reminds our readers to think big and challenge the status quo. You can subscribe to it here –

Cover Photo by 愚木混株 cdd20 on Unsplash