When we order anything online, it comes in an appropriately sized brown package, completely sealed.

Have you ever wondered about the packaging process working behind the scenes?

I visited a parcel warehouse once and had the chance to see the entire packaging process myself. The product started its journey on a conveyor belt which moved it across a number of workstations. At the first station, a worker chose a right sized envelope or box and put the item inside. The package then moved to the next station where it was sealed by another worker. Finally it was weighed and labeled at the final workstation.

Standing there, watching the process, I wondered how many millions of times this process is being executed by thousands of people in various warehouses every single day!

For Amazon alone, the daily number is 1.6 million. Then it should come as no surprise that Amazon is now trying to develop completely automated packaging systems.

This may not be such good news for the people Amazon employs in its warehouses, but let’s look at the technology to understand whether these systems can actually replace human packers.

Couple of weeks back Amazon got a patent which shows the details of Amazon’s technology.

(worth noting is the fact that this patent has a kind code ‘B1’ – which means that Amazon has got it granted as quickly as possible – something which companies often do when they want to quickly bring some tech to the market)

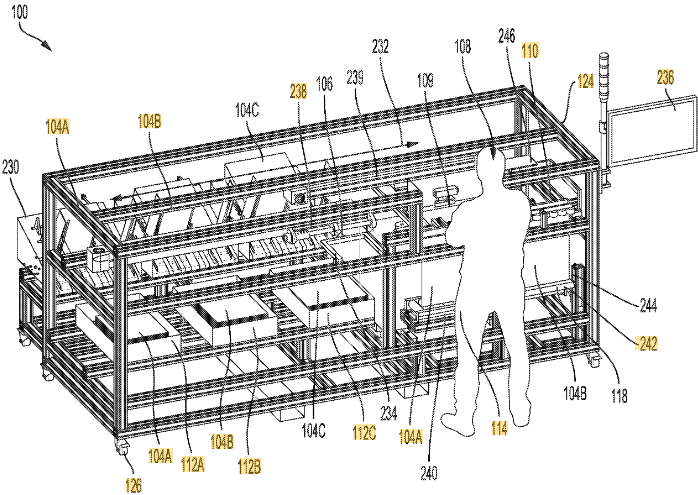

Essentially, the patent describes an item packaging system, which can position, prepare, and seal a package after putting in one or more items into it. Here’s how it looks:

The machine contains a picker and gripper, a loading and a sealing station, and a controller to orchestrate them all.

Interestingly, the entire thing is supported on wheels – perhaps to make the whole system more flexible, and maybe to quickly replace it with another in case it develops any fault (rather than fixing it online – which causes downtime).

The overall process remains more or less the same as it is in a manual workflow. The only (and major) difference being that all work is done by individual modules. The picker picks the package from a container and transfers it to the gripper which puts items (products) into it. The package is then sealed and moved to the output station. The entire process can be operated electronically by a single operator.

There are already packaging machines which are designed to package one particular product (see following video).

I think in this age when online shopping is a significant way of how people make purchases, such technologies would be critical for logistics companies to reduce labor costs, improve information access, and make the whole process more reliable and efficient. On the other hand, the costs for setting up this kind of tech across all warehouses can be significant, and may limit its access to small and medium size players.

If you liked this piece, consider subscribing to our newsletter.

P.S. Cover Photo by Jake Nebov on Unsplash